What is Vibration Measurement?

To ensure you select the best tool for your organisation, it’s important to know if a given vibration sensor or industrial vibration measurement device will interface with your present and future systems, including hardware and asset management software.

The Industrial Internet of Things (IIoT) powers the interface between people, systems and machinery. The connectivity it provides offers maintenance teams new opportunities to extend machine lifespans and increase overall efficiency.

For instance, with condition monitoring tools, reliability professionals can predict asset failures and receive critical machine health data instantly from anywhere. And in the future, vibration analysis combined with machine learning (ML) and artificial intelligence (AI) will be able to drive repair recommendations. But to unlock that future, maintenance teams must be prepared with the right vibration measurement tool kit.

Which Vibration Measurement Tool Should I Use and Why?

Before deciding how to measure vibration, take a look at where your organisation stands in its reliability journey. Are you happy with your current maintenance and operations practices? Do you have the connectivity and infrastructure to implement predictive maintenance (PdM) strategies or a vibration monitoring program?

A lack of resources is a common reason why some organisations struggle with their vibration monitoring programs — including choosing the wrong vibration measurement tool for their needs. Fluke Reliability offers comprehensive remote condition monitoring services, hardware and software to get you started, keep you on track and ensure you succeed.

Vibration Measurement Data is Information Rich

Vibration measurements can help maintenance teams determine the health of machines. By collecting vibration data, teams can detect if and when a machine’s condition changes. Vibration measurement can also be used to diagnose the cause at the root of that change. Crucially, vibration measurements can also offer information for safe machine operation.

Vibration measurement is normally a non-intrusive measurement procedure, and it can be carried out with the machine running in its normal operating condition.

Vibration is simply a sound wave, and each component of a machine has a unique sound (or frequency) that is not detectable to the human ear. Sensors have the ability to detect these.

The amplitude of vibration depends on the magnitude of the excitation force, the mass and stiffness of the system and its damping. Some level of vibration is normal in machinery. Some sources of vibration are machine tolerances, machine structure, bearing design, loading and lubrication, machine mounting, and rolling and rubbing between moving parts.

Five Types of Vibration Measurement Tools

The following vibration measurement tools often help reliability professionals start a predictive maintenance (PdM) or remote condition monitoring program.

1. Handheld Vibration Meter Tools

Best Usage:

A handheld vibration measurement tool like the Fluke 805 FC Vibration Meter is best when you need a highly reliable screening device that can provide repeatable, overall vibration readings. Unlike a pen, the Fluke 805 also measures specific variables, including bearing condition and temperature.

The severity scale is easy to understand and displays simple texts (Good, Satisfactory, Unsatisfactory, Unacceptable) to indicate bearing condition and overall vibration. The vibration measurement device reads a wide range of frequencies, and the data is accessible from anywhere via a smart device, such as a laptop or mobile phone.

2. Portable Vibration Tester Tools

Best Usage:

A portable vibration tester is a strong option when critical machines can be safely and easily reached by a technician. While both handheld vibration testers and vibration analysers can capture vibration data and diagnose machine faults, they do have different capabilities.

The Fluke 810 Vibration Tester uses an analytics engine to diagnose machine issues and provides onsite vibration analysis on one screen. It captures a narrow data window.

3. Handheld Vibration Analyser Tools

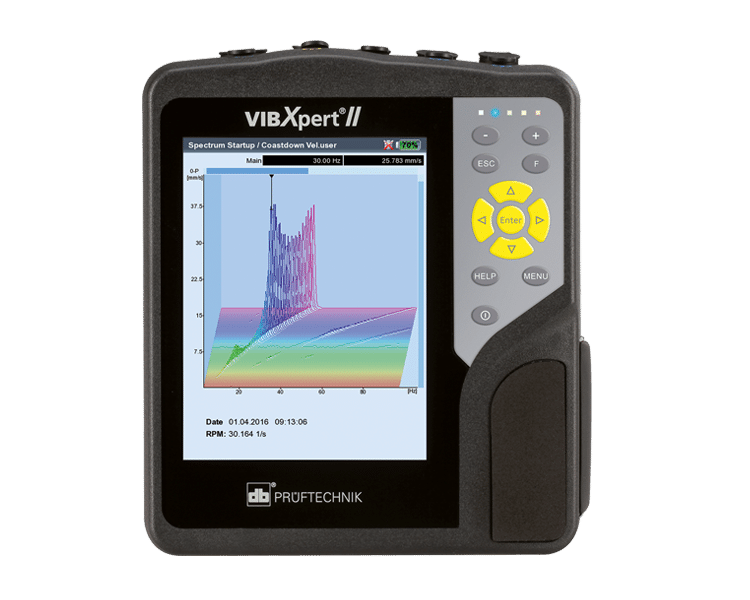

Like vibration testers, a portable vibration analyser can provide users with immediate vibration measurement information about machinery health, including motors, fans and blowers. Both can identify the four most common faults: imbalance, misalignment, looseness, bearing damage. They can also often tell you the fault location and severity.

However, unlike vibration testers, a handheld vibration analyser such as the VIBXpert II by Prüftechnik can collect almost any type of vibration measurement data. These vibration measurement tools also can help teams correct machine imbalance and connect to multiple types of sensors. However, because of their sophistication, vibration analysers often need an expert to interpret the detailed data.

4. Wireless Vibration Analysis Sensor

Best Usage:

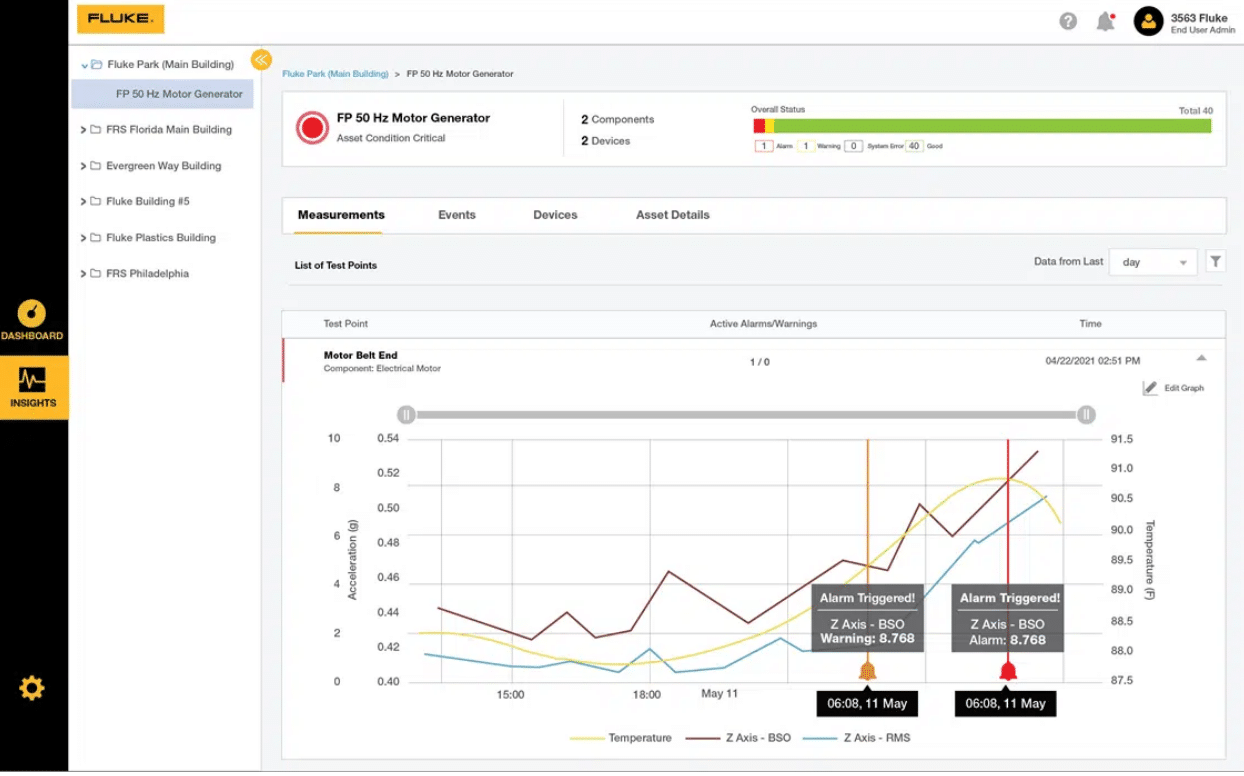

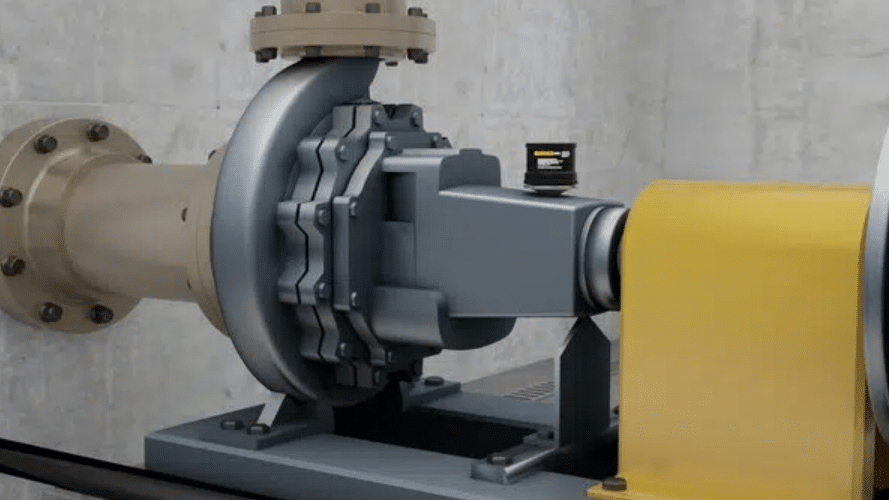

A wireless vibration analysis sensor is best if your organisation has dozens of critical machines. When a critical asset fails, it can shut down production and even harm other machines. These sophisticated sensors alert you of potential machine faults well in advance, including showing the severity of the problem, so you can act to prevent failure.

What Does a Wireless Vibration Analysis Sensor Do?

Wireless vibration sensors like the Fluke 3563 Analysis Vibration Sensor track machine performance and capture in-depth data with a powerful piezo sensor. The data provides reliability professionals with insight into production-critical machinery problems. Quick results give maintenance teams enough time to make informed decisions before machines fail.

5. Wired Vibration Monitoring System

Best Usage:

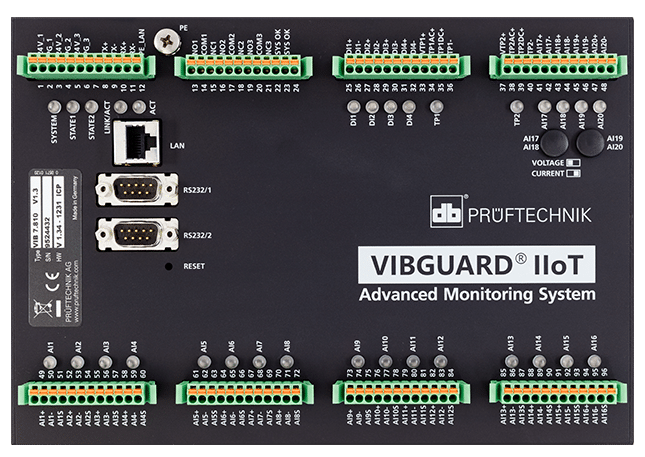

A wired vibration monitoring system is best for condition monitoring of production-critical machines. For example, the VIBGUARD IIoT from Prüftechnik can monitor turbine generators, paper machines, high-speed spindles and multiple drive machines. These advanced vibration measurement tools provide complete vibration analysis for complex machines.

What Does a Wired Vibration Monitoring System Do?

A wired vibration monitoring system captures large amounts of high-resolution vibration measurement data. It allows vibration analysis for a vast range of machinery faults, resonances, processes & structures and enables predictive maintenance.