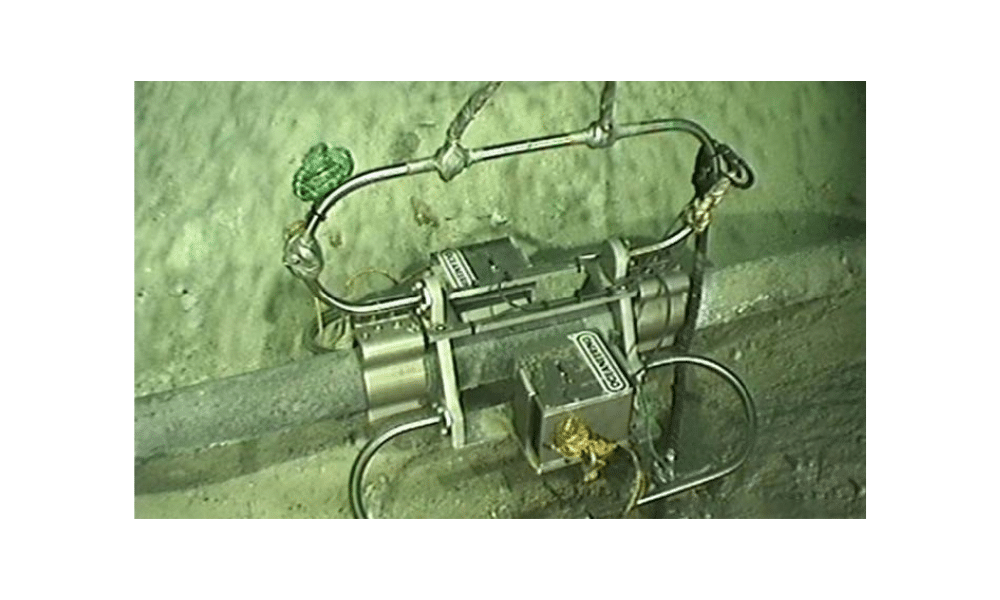

We partnered with Oceaneering to develop a ROV-installable subsea ultrasonic flowmeter.

A non-invasive subsea flow measurement tool was developed for model validation and calibration. This innovative solution provided a suitable alternative to the only other option being a costly workover of the rig.