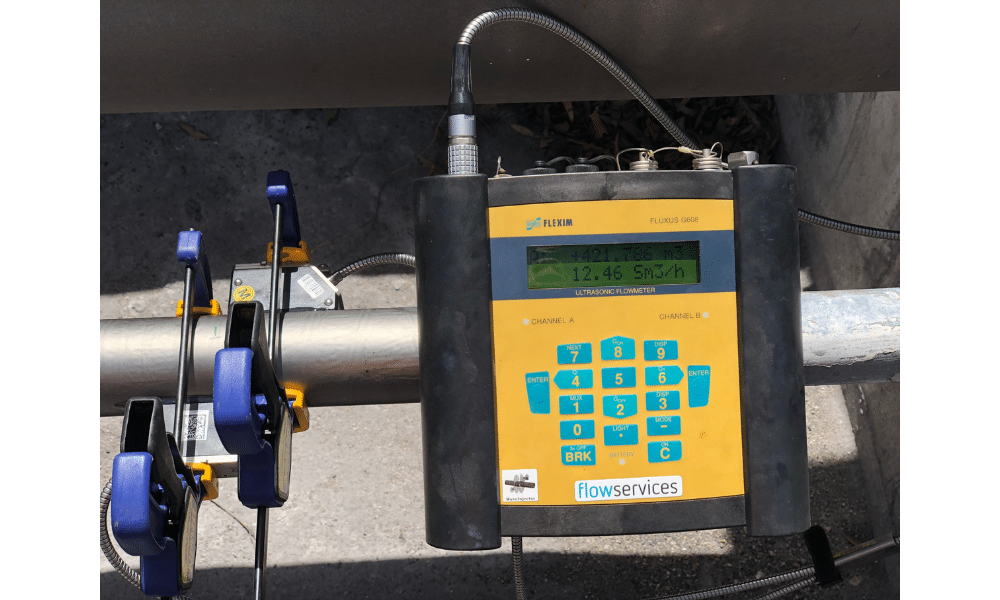

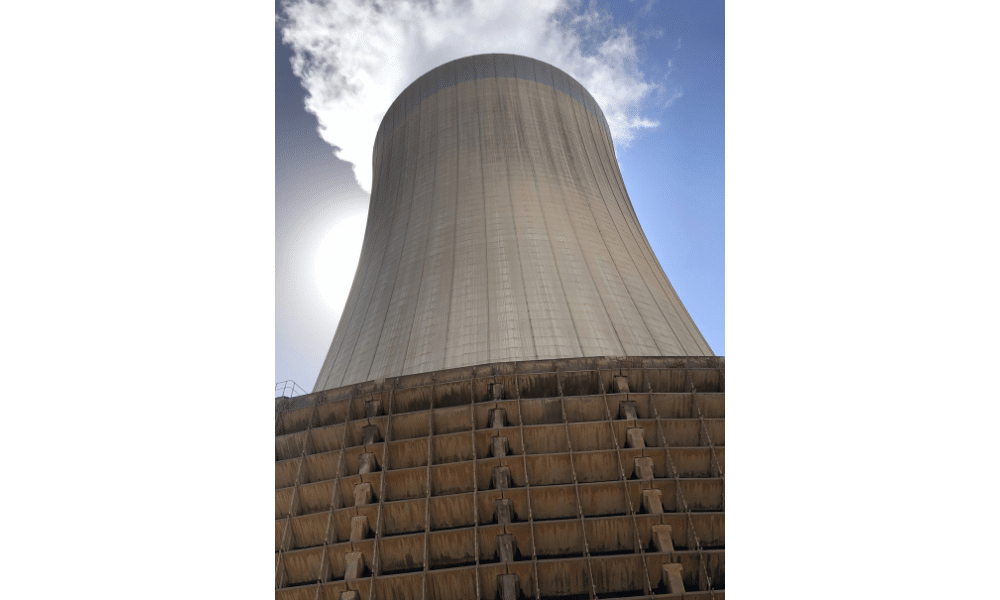

We analysed over 35 compressed air flow measurement locations at a coal fired power station in Queensland.

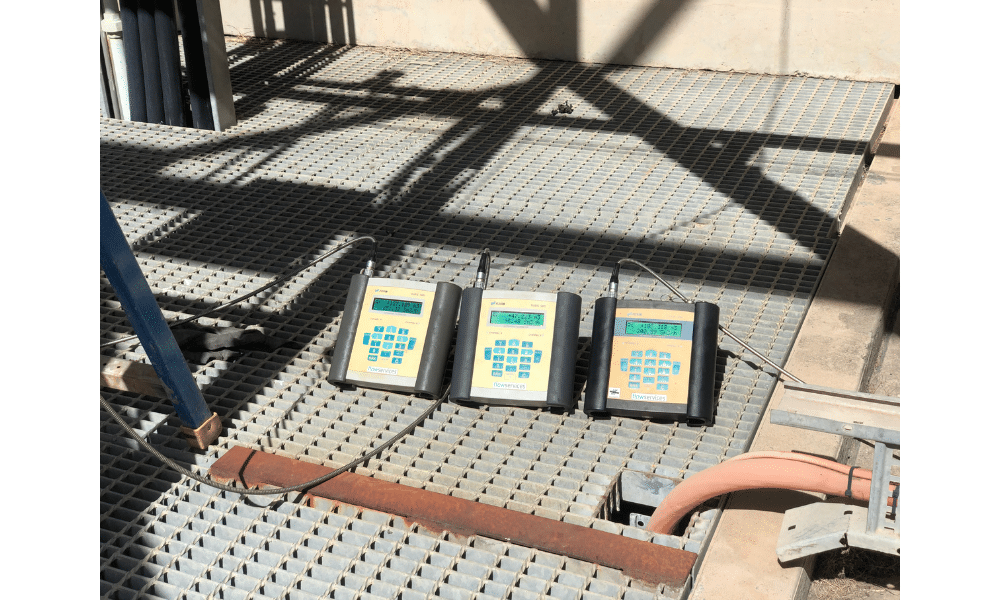

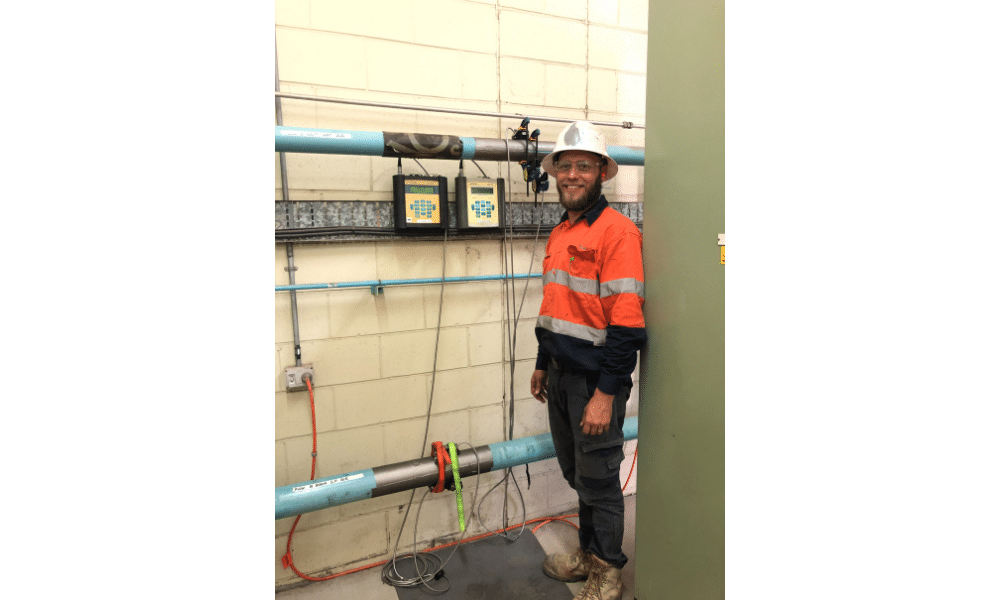

Aquip’s on-site compressed air flow surveys provide an overall view into compressor performance, total air usage and identifying losses in real time. The service was easily deployed without disruption to the process or shutdown of machinery. This ultimately reduces downtime and minimises risks with added cost savings.