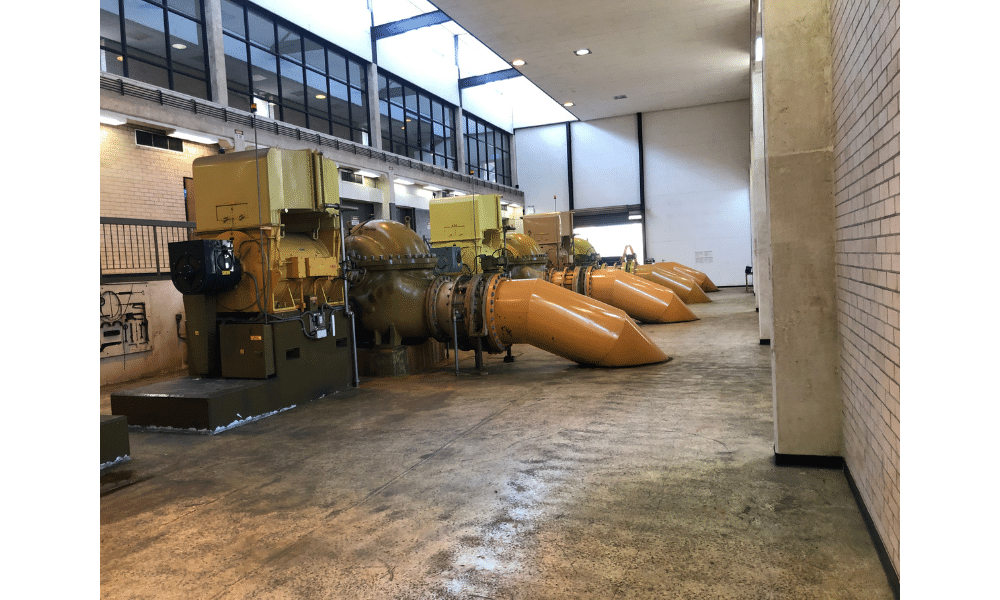

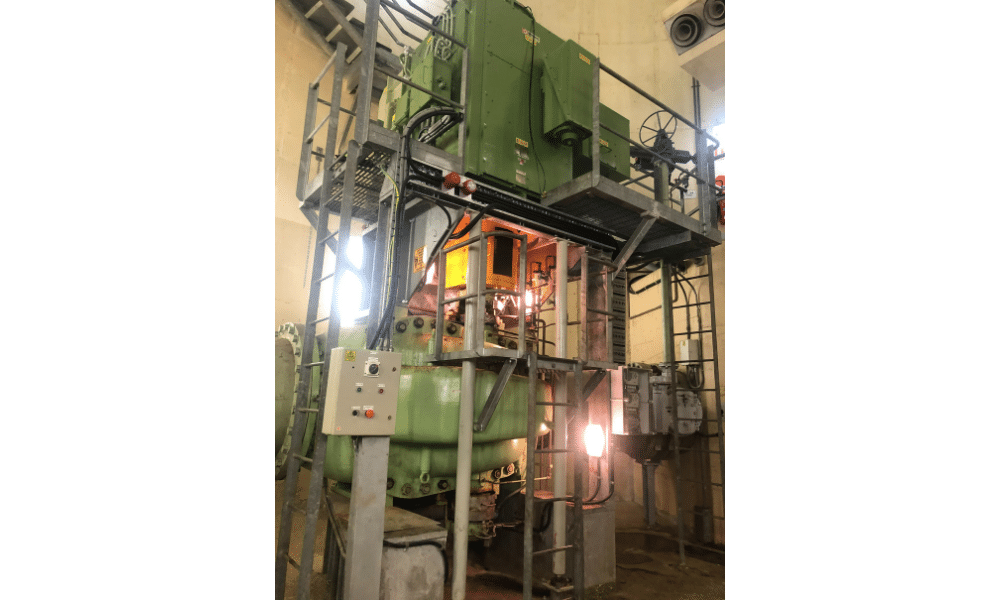

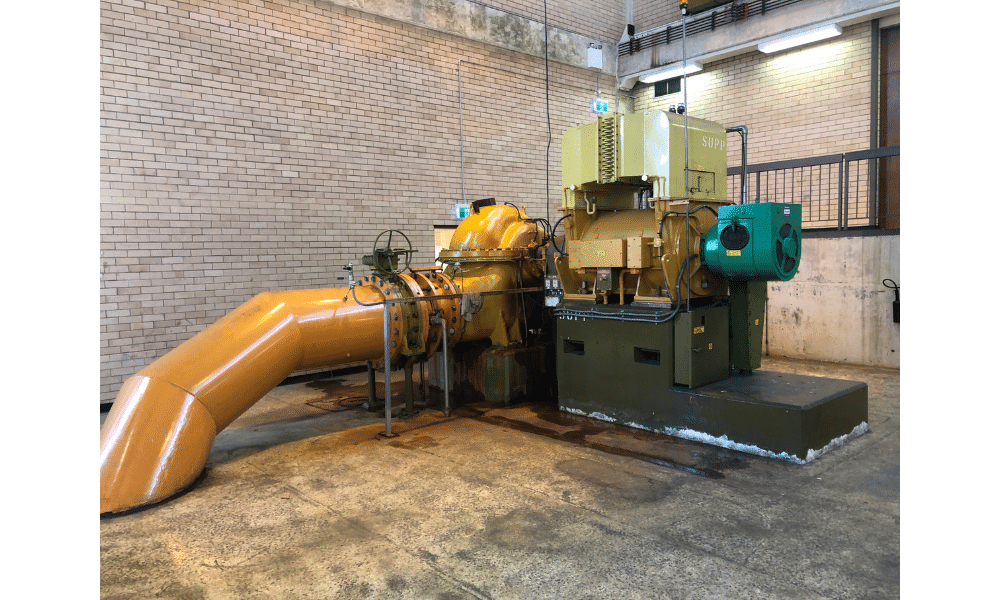

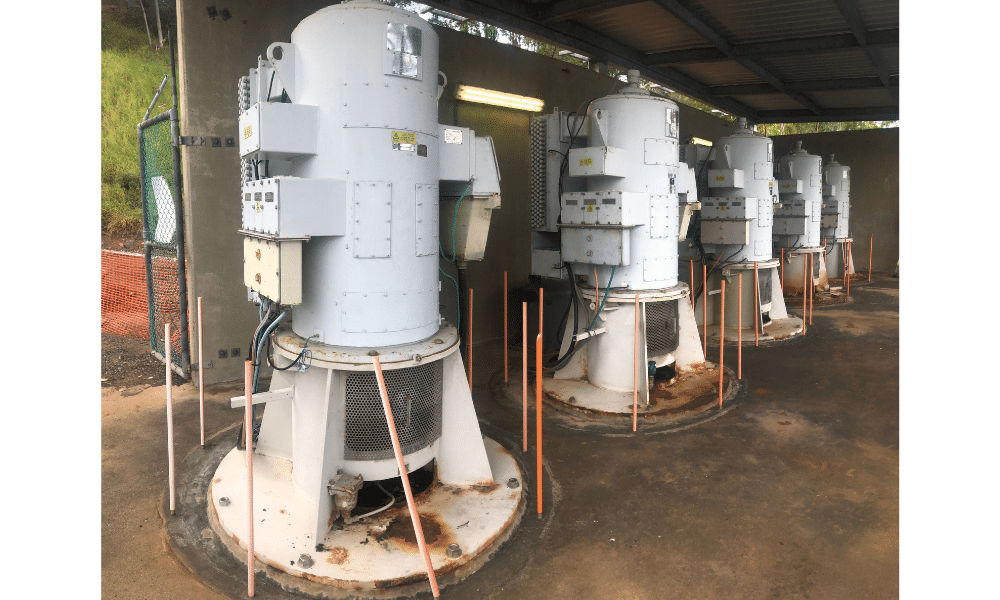

The Aquip team analysed the efficiency of 5 major pump stations within the Queensland irrigation networks.

Our Pump Health Assessment service aims to provide a clear picture of your system’s performance – ultimately saving money, reducing machinery downtime and minimising negative environmental impacts.