Bore alignment doesn’t grab headlines, but anyone who’s worked with turbines, compressors, or heavy rotating equipment knows just how critical it is. A slight misalignment can lead to excessive wear, energy loss, and expensive downtime. Yet, despite its importance, alignment is often done with methods that are either painfully slow or frustratingly inconsistent.

The industry has long relied on piano wires, theodolites, and even dummy shafts – tools that require patience, a steady hand, and a fair amount of improvisation. Some laser-based systems have improved the process, but they come with their own drawbacks: complex setup, sensitivity to drift, or limited flexibility when dealing with real-world machine conditions.

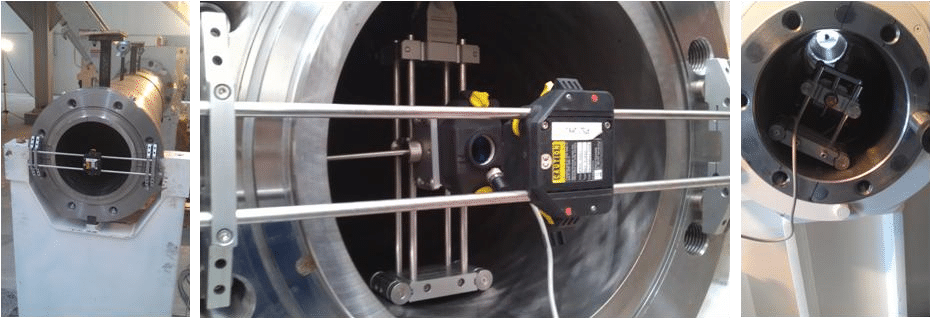

Bore alignment shouldn’t be a drawn-out process filled with workarounds. It should be fast, precise, and intuitive. That’s exactly what CentrAlign delivers: a smarter approach that reduces alignment time while improving accuracy.

Here’s why it stands out as the best bore alignment tool available today.

1. Faster Setup, Less Downtime

Traditional bore alignment methods like dummy shafts or piano strings are slow, cumbersome, and require multiple adjustments before a technician even begins measuring. Some laser-based competitor systems, while more advanced, still require complicated calibration steps that eat into valuable maintenance time.

With CentrAlign, setup is faster and alignment is more efficient:

- One-time mounting with no need for frequent repositioning

- Real-time positioning feedback to eliminate guesswork

- No dummy shafts or manual calibration required

This means less downtime for your machinery and more productive maintenance teams.

2. Unmatched Precision with Advanced Sensor Technology

When it comes to bore alignment, even a small misalignment can have major consequences. That’s why accuracy and repeatability are non-negotiable. CentrAlign Ultra RS5 is designed to provide true bore center measurement, ensuring:

- Determination of eccentricity error for precise alignment

- Ability to measure more than three points per bore for the highest accuracy

- Patented universal pointer brackets with a rotating sensor holder to improve measurement precision and handling

- Measurement of both magnetic and non-magnetic bores with diameters ranging from 45 mm to over 4000 mm

3. User-Friendly Interface with Smart Guidance

Alignment tools should make a technician’s job easier, not harder. Yet, many competing systems have clunky, outdated interfaces that require extensive training and manual input.

CentrAlign simplifies the process with:

- A guided workflow that walks technicians through each step

- A responsive touchscreen interface for easy data entry and visualisation

- Automated corrections that suggest adjustments in real time

With a clear, step-by-step process, even technicians who are new to bore alignment can complete jobs accurately and efficiently.

4. Adaptable to Complex Setups

Not all bore alignments are the same. Some require multiple reference points, while others involve large-diameter bores or complex geometries. Many tools struggle to adapt, forcing maintenance teams to rely on additional accessories or time-consuming manual adjustments.

CentrAlign is built for flexibility:

- Handles large and small bore diameters (from 45 mm to over 4000 mm)

- Works seamlessly on multi-bore alignments

- Easily adjusts for challenging machine geometries

This means whether you’re working on a steam turbine, compressor, or engine, CentrAlign delivers a streamlined, accurate alignment process every time.

5. Reliable Data Logging and Reporting

Alignment isn’t just about getting the job done, it’s about proving it was done right.

CentrAlign eliminates the need for manual record-keeping with:

- Automated data logging that captures every measurement

- Instant reporting features for compliance and audit purposes

- Cloud connectivity to store and access data securely

For high-value assets like turbines, compressors, and power generation equipment, having precise documentation isn’t just useful … it’s essential for regulatory compliance and predictive maintenance planning.

Interested in finding out more about CentrAlign? Contact us HERE

Learn more about PRÜFTECHNIK HERE